Our Services Consist of the following Categories but not limited to

PRESSURE VESSEL

Our services include the fabrication of Pressure Vessels in

compliance with ASME U, R, and S stamp requirements. This

covers shell rolling, cutting, edge preparation, welding of

seams, nozzle installation, and head assembly. We also

fabricate various supports like angle, leg, and skirt types,

along with inspection and pressure testing at the client's

site.

HEAT EXCHANGER

We fabricate various heat exchangers, including Shell & Tube

and Air-Cooled types, at the client's facility. Our scope

includes tube sheet and baffle drilling, bundle assembly,

tube laying, welding, expansion, shell and bonnet

fabrication, nozzle installation, and pressure testing,

along with draining, air blowing, drying, and purging.

AIR COOLED FIN FAN COOLER

Our services include but not limited to fabrication of

cooler header box, drilling and grooving, fabrication of fan

and motor casing, assembly of fined tube with tube sheet,

tube expansion, assembly of headers box with partition

plate, pressure testing, air blowing, and perseverating

Final assembly with complete structure and tube bundle for

conducting run teat and Noice test.

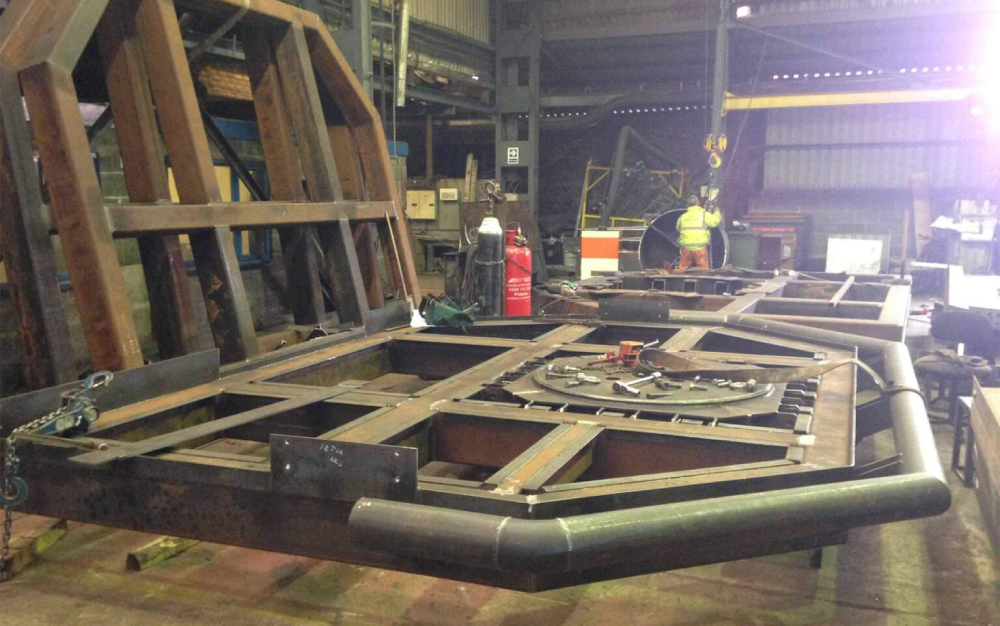

PROCESS SKID PACKAGE

Fabrication, assembly, testing and reinstate of Offshore &

Onshore Skid Package modular units containing Skid Base

Structure, Pressure Vessels, Piping fabrication in

controlled workshops for easy transportation and quick

installation.

MODULAR SKID PACKAGE

Fabrication, assembly, testing and reinstate of modular Skid

Package includes Skid Base Structure, Pressure Vessels,

piping fabrication, testing and reinstatement, support

installation, line alignment, valve and instrumentation and

installation with reference to relevant ISO and PID

drawings. All the works shall be done at client's

fabrication yard.

STRUCTURAL STEEL

(FABRICATION AT SHOP)

We provide all kind of Structural Fabrication works at

client's facility through our highly skilled workforce which

is controlled by a qualified Supervisor, Foremen and

Engineers. Our scope includes prefabrication, trial assembly

and installation at fabrication shop. Our pricing shall be

hourly rate, tonnage basis and lumpsum price etc.,

STRUCTURAL STEEL

(FABRICATION AT SITE)

Fabrication and Installation of Pipe Racks, Pipe Supports,

Handrails, Towers and Walkway Flatforms at different

construction sites under the direct supervision of client

representativeswith high level safety.

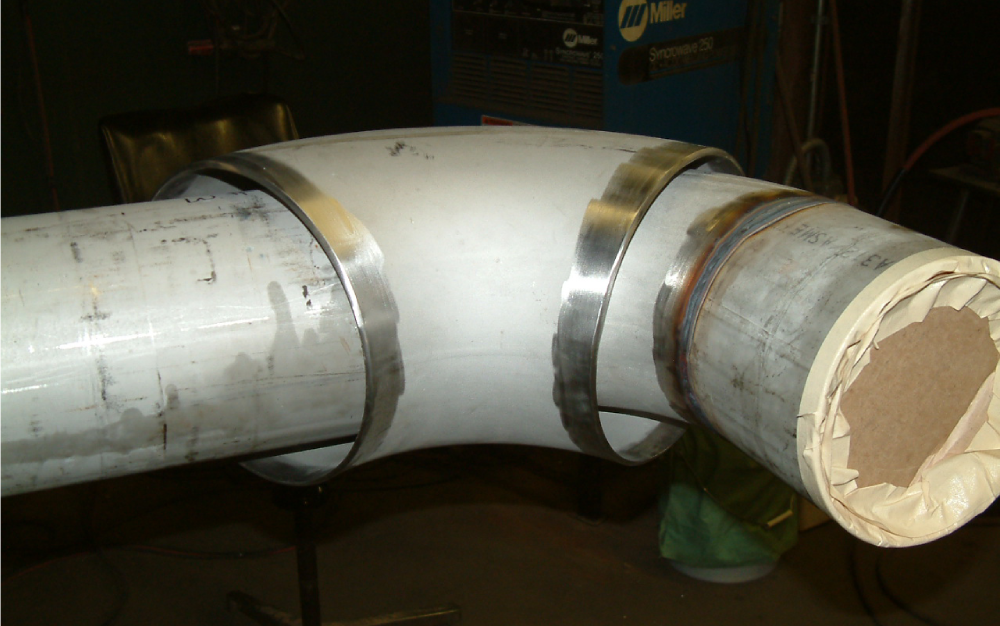

PROCESS PIPING

(REFINERY & PETROCHEMICAL PLANT)

Our service consists of Refinery and Petrochemical plants

piping fabrication, inspection, erection at site,

installation of pipe supports, assembly, Pressure testing

and Reinstatement of relevant piping system.

POWER PIPING

(POWER & DESALINATION PLANT)

Our service consists of Power plants and Desalination

plantslow- and high-pressure piping fabrication, inspection,

erection at site, installation of pipe supports, assembly,

Pressure testing and Reinstatement and test pack clearance

for pre-commissioning activities.

UTILITY PIPING

(INFRASTRUCTURE PROJECT)

Our Scope includes fabrication, assembly, testing and

reinstatement of utility lines such as fire water line,

potable water supply, drainage, HVAC, and fuel distribution

in urban and industrial zones.

JACKET PIPING

We provide all kind of Structural Fabrication works at

client's facility through our highly skilled workforce which

is controlled by a qualified Supervisor, Foremen and

Engineers. Our scope includes prefabrication, trial assembly

and installation at fabrication shop. Our pricing shall be

hourly rate, tonnage basis and lumpsum price etc.,

MARINE SERVICE

Our expert marine team handles vessel refurbishment,

equipment dismantling, thickness surveys, and fabrication of

modules like pressure vessels, piping, and electrical

systems. We also conduct dockside validation and sea trials

to ensure full operational readiness.

PAINTING, FIRE PROOFING, CORROSION RESISTANT COATING

Surface preparation by using sand blasting and grid blasting

with covered Shead to product the environment and to meet

the regulatory requirements. We have specialised affiliated

partners to perform painting on pipe spools, structural

column, Heavy structure bracing and supports and Pressure

Vessels etc. For specialised coatings such as Fire Proofing

and corrosion resistant coating and rubber lining inside the

fabricated pressure vessels in the fabrication shop all over

UAE.

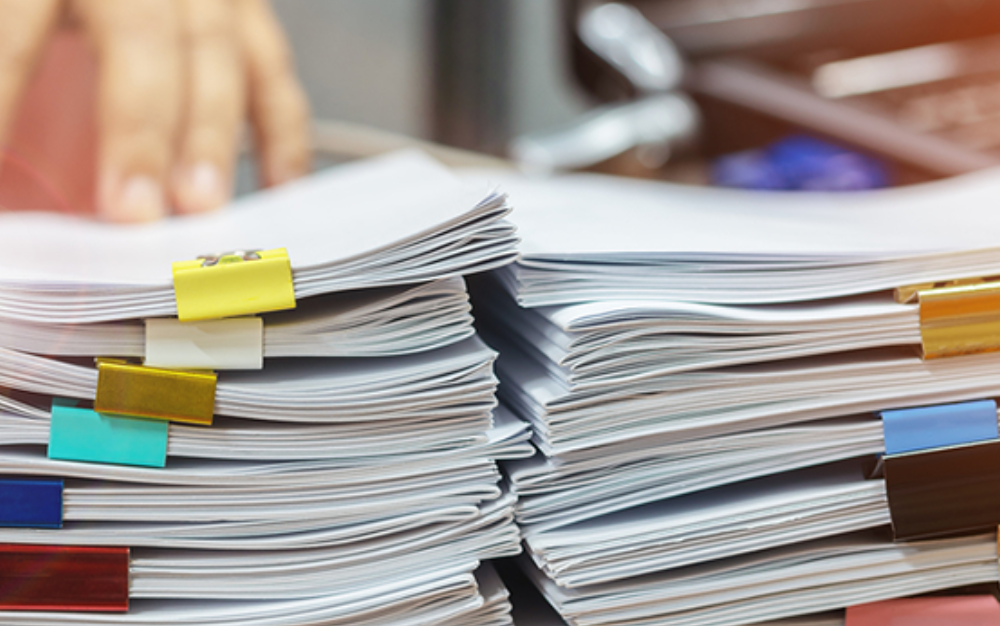

SUBMISSION OF FINAL DOCUMENTATION AND PROJECT HAND OVERING

Our sound quality team has very strong knowledge in the

project specification requirements Accordingly all the

system wise inspection records are stored in controlled area

under direct supervision of store keeper. We will deliver

our project hand overing via fully validated process control

systems to end users, ensuring operational readiness from

day one.

Our welders and welding operators are qualified in accordance with ASME

Section IX, AWS D1.1 with 3rd

Party Certification. The company is focusing on new customers

worldwide as well as keen on providing industrial solutions for

the required Services.

The company's manufacturing

force is being built by an experienced Team of Professional

Engineers having experience of more than 20 years in the

relevant fields.The work crews are being managed by experienced

Foreman and Supervisors. We have Qualified Quality Control

Inspectors in house for Welding and Coating.

Our Team of

skilled work force and Qualified QC inspectors are familiar and

exposed with various Materials such as Carbon Steel, Low Temperature

Carbon Steel, Low Alloy Steel, Austenitic Stainless Steel,

Duplex & Super Duplex Stainless Steel and Nonferrous

material such as Monel, Inconnel, CuNi, Naval Brass and Aluminum

Bronze. We can perform the complete fabrication work at site and

shop as per customer requirements by meeting all Quality and HSE

requirements.